立磨振动大影响生产!立磨产生振动的3类原因,及5种

本文分享立磨振动产生的原因及控制措施。 01立磨振动原因分析. 造成立磨振动的原因较多,主要可以总结为三大类:工艺、设备和电气系统。 1.1 工艺控制. 工艺控制对立磨振动 立磨振动大影响生产!立磨产生振动的3类原因,及5种本文分享立磨振动产生的原因及控制措施。 01立磨振动原因分析. 造成立磨振动的原因较多,主要可以总结为三大类:工艺、设备和电气系统。 1.1 工艺控制. 工艺控制对立磨振动

了解更多

立磨频繁振动的4种原因分析和解决措施-矿机之家

一是操作控制的原因,如料层厚度、喷水、压差、风量、风温、磨压、进料量控制不合理引起的振动; 二是物料的原因,如物料的粒度,物料的易磨性,铁或大块物料进入磨机时磨 立磨频繁振动的4种原因分析和解决措施-矿机之家一是操作控制的原因,如料层厚度、喷水、压差、风量、风温、磨压、进料量控制不合理引起的振动; 二是物料的原因,如物料的粒度,物料的易磨性,铁或大块物料进入磨机时磨

了解更多

造成立式磨粉机振动的原因有哪些?_的设备_磨盘_反馈

造成立磨振动的原因很多,主要可以总结为三大类:工艺、设备和电气系统。 1、工艺控制 工艺控制对立磨振动的影响较大,在生产中大部分立磨的振动均由工 造成立式磨粉机振动的原因有哪些?_的设备_磨盘_反馈造成立磨振动的原因很多,主要可以总结为三大类:工艺、设备和电气系统。 1、工艺控制 工艺控制对立磨振动的影响较大,在生产中大部分立磨的振动均由工

了解更多

了解 || 立磨运行的常见问题以及解决方案_振动 搜狐

立式磨机可以明显感觉到研磨压力上升对磨机振动的影响,当喂料量一定,压力过高,就会产生研磨能力大于物料变成成品所需要的能力,造成磨空产生振动。 了解 || 立磨运行的常见问题以及解决方案_振动 搜狐立式磨机可以明显感觉到研磨压力上升对磨机振动的影响,当喂料量一定,压力过高,就会产生研磨能力大于物料变成成品所需要的能力,造成磨空产生振动。

了解更多

分析立磨振动的原因

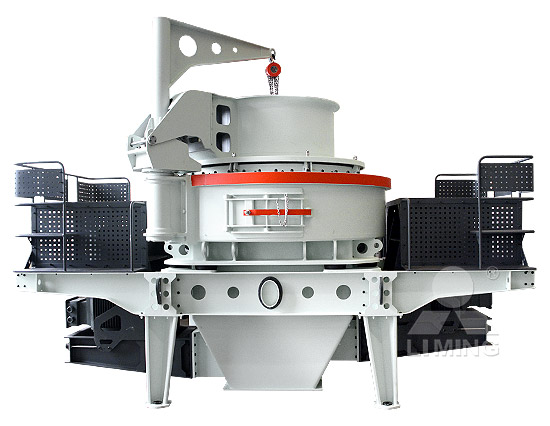

立磨机的内部结构紧凑,而且外部设备较少,能够节约很多空间,减少前期投入。. 立磨还具有扬尘小、噪音低,对环境污染程度低等优点,在磨粉生产种有着广 分析立磨振动的原因 立磨机的内部结构紧凑,而且外部设备较少,能够节约很多空间,减少前期投入。. 立磨还具有扬尘小、噪音低,对环境污染程度低等优点,在磨粉生产种有着广

了解更多

关于立磨机震动的原因和解决措施jingjing1

立磨机产生震动的原因以及解决措施: 1、磨辊和中心支架组合中心偏移磨盘中心,引起的磨机振动。 由于长期的磨损和振动,各个连接部位间隙变大,扭力杆缓冲垫老化、硬化而失去缓冲作用,受冲击厚 关于立磨机震动的原因和解决措施jingjing1 立磨机产生震动的原因以及解决措施: 1、磨辊和中心支架组合中心偏移磨盘中心,引起的磨机振动。 由于长期的磨损和振动,各个连接部位间隙变大,扭力杆缓冲垫老化、硬化而失去缓冲作用,受冲击厚

了解更多

立磨机振动的几个常见的原因及解决办法

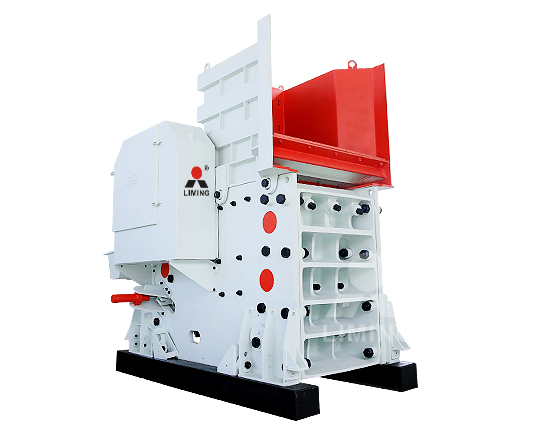

立磨机振动的几个常见的原因及解决办法 发布时间:2020/9/1 9:19:58 作者:同力重机 浏览次数:9222. 立磨机是常见磨粉设备,有常规立磨机、高强度立磨机、 立磨机振动的几个常见的原因及解决办法立磨机振动的几个常见的原因及解决办法 发布时间:2020/9/1 9:19:58 作者:同力重机 浏览次数:9222. 立磨机是常见磨粉设备,有常规立磨机、高强度立磨机、

了解更多

CN107860238A 零排放的方法和工业装置 Google Patents

本发明一种零排放的方法和工业装置,包括工业炉窑、燃烧设备、柯来浦单元、变换分离设备 CN107860238A 零排放的方法和工业装置 Google Patents本发明一种零排放的方法和工业装置,包括工业炉窑、燃烧设备、柯来浦单元、变换分离设备

了解更多

Heat-accumulating lime rotary kiln Google Patents

A heat-accumulating lime rotary kiln comprises two rotary kilns (13), a cooler (16), one or two heat accumulators (4), an air blower (11), a cooling fan (17) and an exhaust emission system. The two rotary kilns (13) are connected via a kiln tail hood (14) and the cooler (16). An upper air port of the heat accumulator (4) is connected to, via a three-way valve (1), Heat-accumulating lime rotary kiln Google PatentsA heat-accumulating lime rotary kiln comprises two rotary kilns (13), a cooler (16), one or two heat accumulators (4), an air blower (11), a cooling fan (17) and an exhaust emission system. The two rotary kilns (13) are connected via a kiln tail hood (14) and the cooler (16). An upper air port of the heat accumulator (4) is connected to, via a three-way valve (1),

了解更多

KR101017982B1 자체증기압력을 이용한 자동 급수식 증기

KR101017982B1 자체증기압력을 이용한 자동 급수식 증기발생장치 Google Patents KR101017982B1 자체증기압력을 이용한 자동 급수식 증기KR101017982B1 자체증기압력을 이용한 자동 급수식 증기발생장치 Google Patents

了解更多

CN115140790A Google Patents

CN115140790A CN202210775936.6A CN202210775936A CN115140790A CN 115140790 A CN115140790 A CN 115140790A CN 202210775936 A CN202210775936 A CN 202210775936A CN 115140790 A CN115140790 A CN 115140790A Authority CN China Prior art keywords temperature sewage heat high temperature energy recovery waste CN115140790A Google PatentsCN115140790A CN202210775936.6A CN202210775936A CN115140790A CN 115140790 A CN115140790 A CN 115140790A CN 202210775936 A CN202210775936 A CN 202210775936A CN 115140790 A CN115140790 A CN 115140790A Authority CN China Prior art keywords temperature sewage heat high temperature energy recovery waste

了解更多

CN111408452B 一种高温工业渣研磨余热利用系统及方法

CN111408452B CN202010299733.5A CN202010299733A CN111408452B CN 111408452 B CN111408452 B CN 111408452B CN 202010299733 A CN202010299733 A CN 202010299733A CN 111408452 B CN111408452 B CN 111408452B Authority CN China Prior art keywords grinding slag waste heat industrial slag temperature industrial Prior art CN111408452B 一种高温工业渣研磨余热利用系统及方法CN111408452B CN202010299733.5A CN202010299733A CN111408452B CN 111408452 B CN111408452 B CN 111408452B CN 202010299733 A CN202010299733 A CN 202010299733A CN 111408452 B CN111408452 B CN 111408452B Authority CN China Prior art keywords grinding slag waste heat industrial slag temperature industrial Prior art

了解更多

CN212237525U 一种高温工业渣研磨余热利用系统 Google

CN212237525U CN202020570000.6U CN202020570000U CN212237525U CN 212237525 U CN212237525 U CN 212237525U CN 202020570000 U CN202020570000 U CN 202020570000U CN 212237525 U CN212237525 U CN 212237525U Authority CN China Prior art keywords grinding waste heat slag industrial slag temperature Prior art date CN212237525U 一种高温工业渣研磨余热利用系统 GoogleCN212237525U CN202020570000.6U CN202020570000U CN212237525U CN 212237525 U CN212237525 U CN 212237525U CN 202020570000 U CN202020570000 U CN 202020570000U CN 212237525 U CN212237525 U CN 212237525U Authority CN China Prior art keywords grinding waste heat slag industrial slag temperature Prior art date

了解更多

CN212237526U 一种高温工业渣研磨装置 Google Patents

CN212237526U CN202020571920.XU CN202020571920U CN212237526U CN 212237526 U CN212237526 U CN 212237526U CN 202020571920 U CN202020571920 U CN 202020571920U CN 212237526 U CN212237526 U CN 212237526U Authority CN China Prior art keywords grinding slag industrial slag stirring mechanism temperature Prior art CN212237526U 一种高温工业渣研磨装置 Google PatentsCN212237526U CN202020571920.XU CN202020571920U CN212237526U CN 212237526 U CN212237526 U CN 212237526U CN 202020571920 U CN202020571920 U CN 202020571920U CN 212237526 U CN212237526 U CN 212237526U Authority CN China Prior art keywords grinding slag industrial slag stirring mechanism temperature Prior art

了解更多

CN111900763A Google Patents

CN111900763A CN202010785122.1A CN202010785122A CN111900763A CN 111900763 A CN111900763 A CN 111900763A CN 202010785122 A CN202010785122 A CN 202010785122A CN 111900763 A CN111900763 A CN 111900763A Authority CN China Prior art keywords photovoltaic cell module power demand side adjusting Prior art date CN111900763A Google PatentsCN111900763A CN202010785122.1A CN202010785122A CN111900763A CN 111900763 A CN111900763 A CN 111900763A CN 202010785122 A CN202010785122 A CN 202010785122A CN 111900763 A CN111900763 A CN 111900763A Authority CN China Prior art keywords photovoltaic cell module power demand side adjusting Prior art date

了解更多

余热发电设备 北极星环保网

类别:余热余压 来源:北极星环保网 15:20:30. 节能服务公司仟亿达浅析 余热发 电设备 注重控制床温上升率,防止出现爆燃景象。. 革新流化 余热发电设备 北极星环保网类别:余热余压 来源:北极星环保网 15:20:30. 节能服务公司仟亿达浅析 余热发 电设备 注重控制床温上升率,防止出现爆燃景象。. 革新流化

了解更多

CN107860238B 零排放的工业装置 Google Patents

本发明一种零排放的方法和工业装置,包括工业炉窑、燃烧设备、柯来浦单元、变换分离设备 CN107860238B 零排放的工业装置 Google Patents本发明一种零排放的方法和工业装置,包括工业炉窑、燃烧设备、柯来浦单元、变换分离设备

了解更多

waste heat recovery power plant in Japanese ichacha.net

waste heat recovery power plant 廃熱利用火力発電所[機械] "power plant waste heat" in Japanese: 発電所廃熱{はつでんしょ はいねつ} "waste product recovery power plant" in Japanese: 廃物利用火力発電所{はいぶつ りよう かりょく はつでんしょ} "waste heat recovery power generation" in Japanese: 廃熱回収発電{はいねつ waste heat recovery power plant in Japanese ichacha.netwaste heat recovery power plant 廃熱利用火力発電所[機械] "power plant waste heat" in Japanese: 発電所廃熱{はつでんしょ はいねつ} "waste product recovery power plant" in Japanese: 廃物利用火力発電所{はいぶつ りよう かりょく はつでんしょ} "waste heat recovery power generation" in Japanese: 廃熱回収発電{はいねつ

了解更多

US9551241B2 Waste heat recovery power generation plant for

US9551241B2 US14/412,554 US201214412554A US9551241B2 US 9551241 B2 US9551241 B2 US 9551241B2 US 201214412554 A US201214412554 A US 201214412554A US 9551241 B2 US9551241 B2 US 9551241B2 Authority US United States Prior art keywords waste heat steam sintering hot water supplied Prior art date 2012-07 US9551241B2 Waste heat recovery power generation plant for US9551241B2 US14/412,554 US201214412554A US9551241B2 US 9551241 B2 US9551241 B2 US 9551241B2 US 201214412554 A US201214412554 A US 201214412554A US 9551241 B2 US9551241 B2 US 9551241B2 Authority US United States Prior art keywords waste heat steam sintering hot water supplied Prior art date 2012-07

了解更多

CN114436449A 一种余热发电循环水处理装置 Google Patents

CN114436449A CN202210160730.2A CN202210160730A CN114436449A CN 114436449 A CN114436449 A CN 114436449A CN 202210160730 A CN202210160730 A CN 202210160730A CN 114436449 A CN114436449 A CN 114436449A Authority CN China Prior art keywords circulating water water circulating waste heat power generation Prior CN114436449A 一种余热发电循环水处理装置 Google PatentsCN114436449A CN202210160730.2A CN202210160730A CN114436449A CN 114436449 A CN114436449 A CN 114436449A CN 202210160730 A CN202210160730 A CN 202210160730A CN 114436449 A CN114436449 A CN 114436449A Authority CN China Prior art keywords circulating water water circulating waste heat power generation Prior

了解更多

KR101017982B1 자체증기압력을 이용한 자동 급수식 증기

본 발명은 증기탱크에 저장된 자체 증기압력을 이용하여 상기 증기탱크에 물을 원활하게 공급하면서 필요한 증기를 지속적으로 발생함은 물론 증기발생과정에서 외부로의 열손실을 최소화하여 증기발생에 소요되는 에너지를 절감하며, 급수용 압력탱크에 충분한 증기압력을 공급한 후 비로소 상기 KR101017982B1 자체증기압력을 이용한 자동 급수식 증기본 발명은 증기탱크에 저장된 자체 증기압력을 이용하여 상기 증기탱크에 물을 원활하게 공급하면서 필요한 증기를 지속적으로 발생함은 물론 증기발생과정에서 외부로의 열손실을 최소화하여 증기발생에 소요되는 에너지를 절감하며, 급수용 압력탱크에 충분한 증기압력을 공급한 후 비로소 상기

了解更多

CN114436449B 一种余热发电循环水处理装置 Google Patents

CN114436449B CN202210160730.2A CN202210160730A CN114436449B CN 114436449 B CN114436449 B CN 114436449B CN 202210160730 A CN202210160730 A CN 202210160730A CN 114436449 B CN114436449 B CN 114436449B Authority CN China Prior art keywords circulating water water waste heat power generation circulating Prior CN114436449B 一种余热发电循环水处理装置 Google PatentsCN114436449B CN202210160730.2A CN202210160730A CN114436449B CN 114436449 B CN114436449 B CN 114436449B CN 202210160730 A CN202210160730 A CN 202210160730A CN 114436449 B CN114436449 B CN 114436449B Authority CN China Prior art keywords circulating water water waste heat power generation circulating Prior

了解更多

KR101058430B1 증기압력을 이용한 발전소용 급수 펌핑

본 발명은 발전소에서 사용하는 증기발생기에 저장된 증기압력을 이용하여 상기 증기발생기에 별도의 대용량 펌프 및 복수기를 사용하지 않고서도 더욱 신속하고 원활하게 물을 공급하는 증기압력을 이용한 발전소용 급수 펌핑장치에 관한 것이다. 이러한 본 KR101058430B1 증기압력을 이용한 발전소용 급수 펌핑본 발명은 발전소에서 사용하는 증기발생기에 저장된 증기압력을 이용하여 상기 증기발생기에 별도의 대용량 펌프 및 복수기를 사용하지 않고서도 더욱 신속하고 원활하게 물을 공급하는 증기압력을 이용한 발전소용 급수 펌핑장치에 관한 것이다. 이러한 본

了解更多

CN103827583B 排水回收系统 Google Patents

CN103827583B CN201280047730.6A CN201280047730A CN103827583B CN 103827583 B CN103827583 B CN 103827583B CN 201280047730 A CN201280047730 A CN 201280047730A CN 103827583 B CN103827583 B CN 103827583B Authority CN China Prior art keywords draining auxiliary tank steam tank boiler Prior art date CN103827583B 排水回收系统 Google PatentsCN103827583B CN201280047730.6A CN201280047730A CN103827583B CN 103827583 B CN103827583 B CN 103827583B CN 201280047730 A CN201280047730 A CN 201280047730A CN 103827583 B CN103827583 B CN 103827583B Authority CN China Prior art keywords draining auxiliary tank steam tank boiler Prior art date

了解更多

CN108187082A 高温蒸汽杀菌锅双管式稳流蒸汽喷射器

CN108187082A CN201810197769.5A CN201810197769A CN108187082A CN 108187082 A CN108187082 A CN 108187082A CN 201810197769 A CN201810197769 A CN 201810197769A CN 108187082 A CN108187082 A CN 108187082A Authority CN China Prior art keywords cylinder steam playpipe circulation current stabilization Prior art date CN108187082A 高温蒸汽杀菌锅双管式稳流蒸汽喷射器CN108187082A CN201810197769.5A CN201810197769A CN108187082A CN 108187082 A CN108187082 A CN 108187082A CN 201810197769 A CN201810197769 A CN 201810197769A CN 108187082 A CN108187082 A CN 108187082A Authority CN China Prior art keywords cylinder steam playpipe circulation current stabilization Prior art date

了解更多

IN2015DN00036A - Google Patents

IN2015DN00036A IN36DEN2015A IN2015DN00036A IN 2015DN00036 A IN2015DN00036 A IN 2015DN00036A IN 36DEN2015 A IN36DEN2015 A IN 36DEN2015A IN 2015DN00036 A IN2015DN00036 A IN 2015DN00036A Authority IN India Prior art keywords boiler exhaust gas sintering device hot water sintering Prior art date Application number IN2015DN00036A - Google PatentsIN2015DN00036A IN36DEN2015A IN2015DN00036A IN 2015DN00036 A IN2015DN00036 A IN 2015DN00036A IN 36DEN2015 A IN36DEN2015 A IN 36DEN2015A IN 2015DN00036 A IN2015DN00036 A IN 2015DN00036A Authority IN India Prior art keywords boiler exhaust gas sintering device hot water sintering Prior art date Application number

了解更多

CN103836604A 一种新型余热回收热电联供系统 Google Patents

CN103836604A CN201410074142.2A CN201410074142A CN103836604A CN 103836604 A CN103836604 A CN 103836604A CN 201410074142 A CN201410074142 A CN 201410074142A CN 103836604 A CN103836604 A CN 103836604A Authority CN China Prior art keywords waste heat generating set steam heat boiler valve Prior art date 2014 CN103836604A 一种新型余热回收热电联供系统 Google PatentsCN103836604A CN201410074142.2A CN201410074142A CN103836604A CN 103836604 A CN103836604 A CN 103836604A CN 201410074142 A CN201410074142 A CN 201410074142A CN 103836604 A CN103836604 A CN 103836604A Authority CN China Prior art keywords waste heat generating set steam heat boiler valve Prior art date 2014

了解更多

IN2015DN00036A - Google Patents

IN2015DN00036A IN36DEN2015A IN2015DN00036A IN 2015DN00036 A IN2015DN00036 A IN 2015DN00036A IN 36DEN2015 A IN36DEN2015 A IN 36DEN2015A IN 2015DN00036 A IN2015DN00036 A IN 2015DN00036A Authority IN India Prior art keywords boiler exhaust gas sintering device hot water sintering Prior art date Application number IN2015DN00036A - Google PatentsIN2015DN00036A IN36DEN2015A IN2015DN00036A IN 2015DN00036 A IN2015DN00036 A IN 2015DN00036A IN 36DEN2015 A IN36DEN2015 A IN 36DEN2015A IN 2015DN00036 A IN2015DN00036 A IN 2015DN00036A Authority IN India Prior art keywords boiler exhaust gas sintering device hot water sintering Prior art date Application number

了解更多

KR101161694B1 증기압력을 이용한 진공 흡입장치 Google

본 발명은 증기압력을 이용하여 가압 급수탱크의 내부에 생성한 진공압력에 의한 강한 흡입력으로 상기 가압 급수탱크에 물을 공급하는 증기압력을 이용한 진공 흡입장치에 관한 것이다. 이러한 본 발명은 증기압력을 이용하여 가압 급수탱크에 일시적으로 진공압력을 생성하여 강한 흡입력으로 KR101161694B1 증기압력을 이용한 진공 흡입장치 Google본 발명은 증기압력을 이용하여 가압 급수탱크의 내부에 생성한 진공압력에 의한 강한 흡입력으로 상기 가압 급수탱크에 물을 공급하는 증기압력을 이용한 진공 흡입장치에 관한 것이다. 이러한 본 발명은 증기압력을 이용하여 가압 급수탱크에 일시적으로 진공압력을 생성하여 강한 흡입력으로

了解更多

CN102817849B 喷水式蒸汽压缩机 Google Patents

CN102817849B CN201210181167.3A CN201210181167A CN102817849B CN 102817849 B CN102817849 B CN 102817849B CN 201210181167 A CN201210181167 A CN 201210181167A CN 102817849 B CN102817849 B CN 102817849B Authority CN China Prior art keywords steam water make compressor ejection Prior art date CN102817849B 喷水式蒸汽压缩机 Google PatentsCN102817849B CN201210181167.3A CN201210181167A CN102817849B CN 102817849 B CN102817849 B CN 102817849B CN 201210181167 A CN201210181167 A CN 201210181167A CN 102817849 B CN102817849 B CN 102817849B Authority CN China Prior art keywords steam water make compressor ejection Prior art date

了解更多

CN202970816U 烧结设备用废热回收发电设备 Google Patents

CN202970816U CN2012204592014U CN201220459201U CN202970816U CN 202970816 U CN202970816 U CN 202970816U CN 2012204592014 U CN2012204592014 U CN 2012204592014U CN 201220459201 U CN201220459201 U CN 201220459201U CN 202970816 U CN202970816 U CN 202970816U Authority CN China Prior art keywords CN202970816U 烧结设备用废热回收发电设备 Google PatentsCN202970816U CN2012204592014U CN201220459201U CN202970816U CN 202970816 U CN202970816 U CN 202970816U CN 2012204592014 U CN2012204592014 U CN 2012204592014U CN 201220459201 U CN201220459201 U CN 201220459201U CN 202970816 U CN202970816 U CN 202970816U Authority CN China Prior art keywords

了解更多

KR101058430B1 증기압력을 이용한 발전소용 급수 펌핑

KR101058430B1 증기압력을 이용한 발전소용 급수 펌핑장치 Google Patents KR101058430B1 증기압력을 이용한 발전소용 급수 펌핑KR101058430B1 증기압력을 이용한 발전소용 급수 펌핑장치 Google Patents

了解更多

US9551241B2 Waste heat recovery power generation plant for

US9551241B2 US14/412,554 US201214412554A US9551241B2 US 9551241 B2 US9551241 B2 US 9551241B2 US 201214412554 A US201214412554 A US 201214412554A US 9551241 B2 US9551241 B2 US 9551241B2 Authority US United States Prior art keywords waste heat steam sintering hot water supplied Prior art date 2012-07 US9551241B2 Waste heat recovery power generation plant for US9551241B2 US14/412,554 US201214412554A US9551241B2 US 9551241 B2 US9551241 B2 US 9551241B2 US 201214412554 A US201214412554 A US 201214412554A US 9551241 B2 US9551241 B2 US 9551241B2 Authority US United States Prior art keywords waste heat steam sintering hot water supplied Prior art date 2012-07

了解更多

US9551241B2 Waste heat recovery power generation plant for

US9551241B2 US14/412,554 US201214412554A US9551241B2 US 9551241 B2 US9551241 B2 US 9551241B2 US 201214412554 A US201214412554 A US 201214412554A US 9551241 B2 US9551241 B2 US 9551241B2 Authority US United States Prior art keywords waste heat steam sintering hot water supplied Prior art date 2012-07 US9551241B2 Waste heat recovery power generation plant for US9551241B2 US14/412,554 US201214412554A US9551241B2 US 9551241 B2 US9551241 B2 US 9551241B2 US 201214412554 A US201214412554 A US 201214412554A US 9551241 B2 US9551241 B2 US 9551241B2 Authority US United States Prior art keywords waste heat steam sintering hot water supplied Prior art date 2012-07

了解更多

KR101058430B1 증기압력을 이용한 발전소용 급수 펌핑

KR101058430B1 증기압력을 이용한 발전소용 급수 펌핑장치 Google Patents KR101058430B1 증기압력을 이용한 발전소용 급수 펌핑KR101058430B1 증기압력을 이용한 발전소용 급수 펌핑장치 Google Patents

了解更多

CN101737332A 蒸气压缩装置 Google Patents

CN101737332A CN200910212003A CN200910212003A CN101737332A CN 101737332 A CN101737332 A CN 101737332A CN 200910212003 A CN200910212003 A CN 200910212003A CN 200910212003 A CN200910212003 A CN 200910212003A CN 101737332 A CN101737332 A CN 101737332A Authority CN China Prior art keywords CN101737332A 蒸气压缩装置 Google PatentsCN101737332A CN200910212003A CN200910212003A CN101737332A CN 101737332 A CN101737332 A CN 101737332A CN 200910212003 A CN200910212003 A CN 200910212003A CN 200910212003 A CN200910212003 A CN 200910212003A CN 101737332 A CN101737332 A CN 101737332A Authority CN China Prior art keywords

了解更多

CN208995453U Google Patents

CN208995453U CN201821546347.6U CN201821546347U CN208995453U CN 208995453 U CN208995453 U CN 208995453U CN 201821546347 U CN201821546347 U CN 201821546347U CN 208995453 U CN208995453 U CN 208995453U Authority CN China Prior art keywords steam waste heat heat boiler gasification furnace coal gasification CN208995453U Google PatentsCN208995453U CN201821546347.6U CN201821546347U CN208995453U CN 208995453 U CN208995453 U CN 208995453U CN 201821546347 U CN201821546347 U CN 201821546347U CN 208995453 U CN208995453 U CN 208995453U Authority CN China Prior art keywords steam waste heat heat boiler gasification furnace coal gasification

了解更多